General information : Features : Range : Brand : Model :

Description

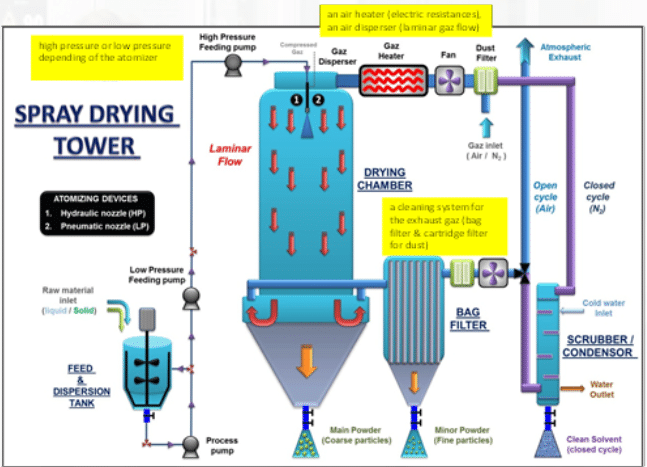

The product (suspension) is pulverized through a nozzle inside a drying chamber (nozzle tower type, 10,5 high and 2m diameter). Three spraying modes are available:

– Parallel flow pressure nozzle

– Parallel flow bi-fluidic nozzle

– counterflow bi-fluidic fountain

The drying media, air or nitrogen (in the case of suspensions in organic solvents) is heated thanks to an electric battery, able to heat until 250°C.

When the spray dryer is used in closed-loop (under nitrogen), a condenser-washer is put after the bag filter, in order to condense solvent vapor, evaporated beforehand, before gas recirculation to the heating battery, which feeds the wahsing chamber.

The largest particles are recovered at the bottom of the chamber, the drying gas (which contains the finest particles) is then filtered in a bag filter before rejection to atmosphere.