Successful scale up for MOFs

Axel’One has launched two consecutive MOF (Metal-Organic Frameworks) production campaigns in order to demonstrate the feasibility of mass producing these metal-organic frameworks over a few days.

This campaign relies on the results of the European ProDia project, which aims to develop production methods for MOFs for various industrial applications such as pesticide respirator masks, air and water purification, anti-bacterial agents, data centre cooling, etc. For example, these structures with nano-sized cavities are already used in filters for extractor hoods to capture odours. The MOFs produced on Axel’One platforms are distinguished by their excellent absorption properties, particularly for volatile organic compounds.

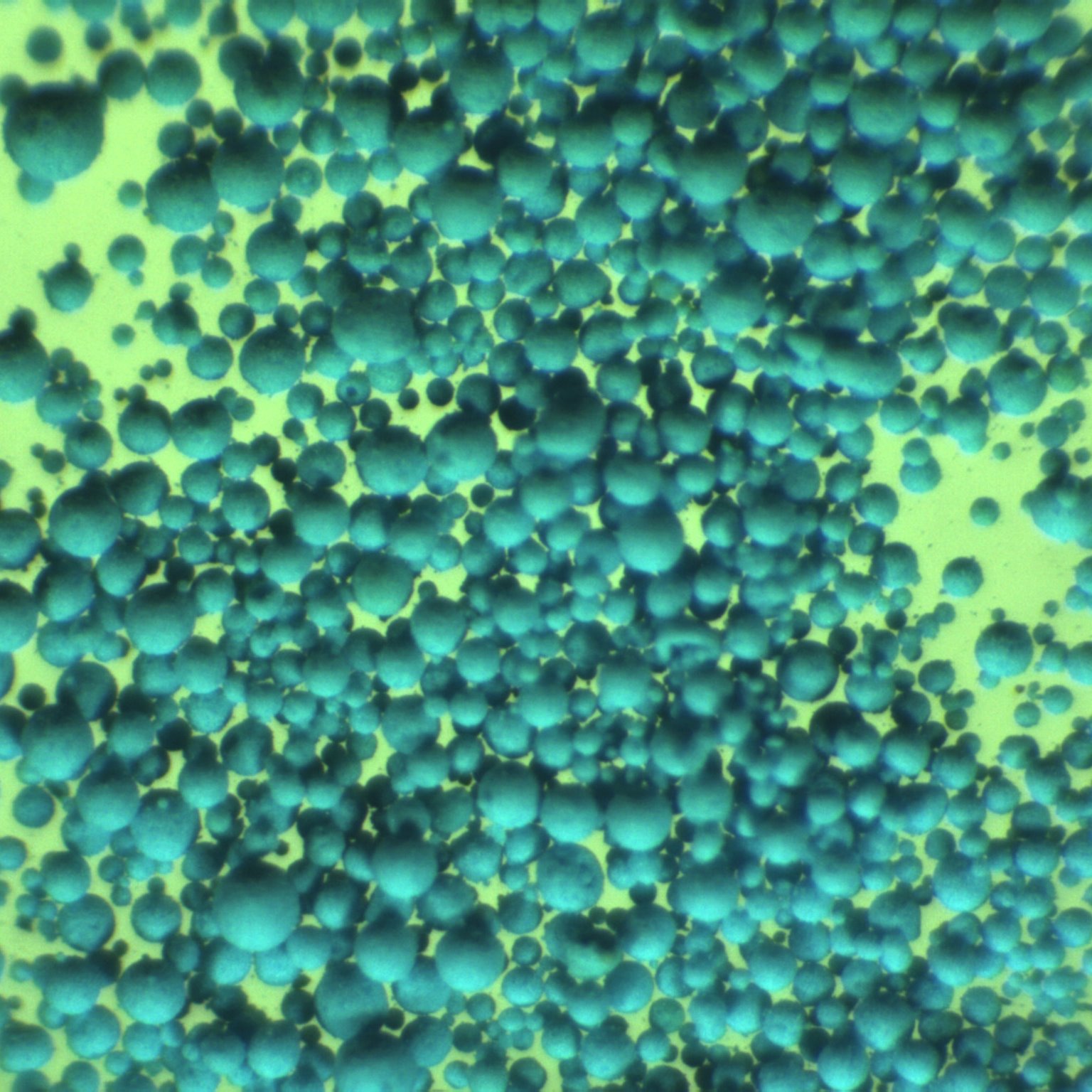

The campaign’s goal was to produce 50 kg of MOF by atomisation in a few days with a single operator, as well as to optimise operating parameters and to increase productivity. Two successive productions were carried out: an HKUST-1 and a ZIF-8 production. In order to obtain the desired result, David Farusseng, research director at the CNRS (IRCE Lyon), and his team, worked in close collaboration with ICN2 and Axel’One in order to develop an atomisation process. This method makes it possible to manufacture crystal objects in the form of small pellets of 50µm in diameter, easily exploitable by innovative industries and SMEs.

For this production, Axel’One benefited from large-scale equipment (Sysprod project: funding from the Auvergne-Rhône-Alpes region, Greater Lyon, the French State, the University of Lyon, the CNRS and IFPEN), such as a 10 m-tall atomiser. This resulted in the production of 53 kg of HKUST-1 on the first day and 30 kg of ZIF8 on the following campaign.

Widely broadcast on Twitter, this pilot campaign received more than 60,000 views worldwide and strengthened the Axel’One/IRCE Lyon partnership aimed at developing industrial processes for the production of MOFs that comply with market expectations.